ASMI News

When machinery must deliver a safe, reliable performance even in the most extreme and aggressive environments it¡¯s not just the performance and resilience of the key components in the system that¡¯s crucial to operational success. Unrivalled technical support and a clear understanding of the challenges can make a big difference, especially if provided by a team of outstanding engineering talents.

The Nuclear research, aerospace and semi-conductor industries are a few examples of where the demands placed upon components are often classified as ¡®extreme¡¯ and where overall performance is often regarded as ¡®cutting edge¡¯. Furthermore, the ability to overcome supply issues (especially with semi-conductors) is a major factor in the demand for more automated processes.

The Nuclear research, aerospace and semi-conductor industries are a few examples of where the demands placed upon components are often classified as ¡®extreme¡¯ and where overall performance is often regarded as ¡®cutting edge¡¯. Furthermore, the ability to overcome supply issues (especially with semi-conductors) is a major factor in the demand for more automated processes.

Bearings are a key component in many of these systems and Oxfordshire based precision bearing specialists CARTER MANUFACTURING have an excellent reputation for their competence and understanding. Their diverse engineering talents are drawn from the local cutting-edge technical environment of ultra-high vacuum, cryogenic, motor sport and space exploration industries. Due to their success in these markets, they¡¯ve recently opened locations in the USA and Spain to better support their customers.

Choosing the right Materials

Carter offer a range of bearing products specifically aimed at very aggressive environments including thin section bearings, ceramic bearings, plastic bearings, stainless steel cam followers and linear bearings. Traditionally, bearings are manufactured from 52100 Chrome Steel but this is limited in its ability to be used in applications where severe environmental conditions exist (such as extreme high or low temperatures).

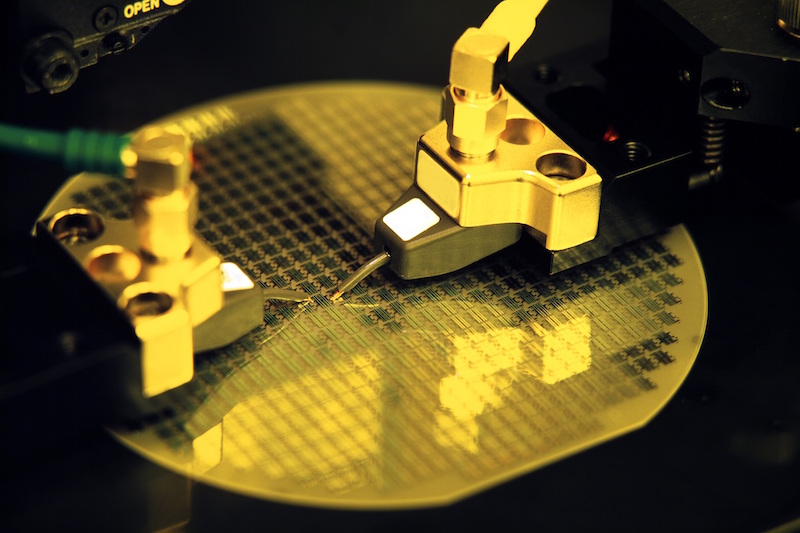

A good example is semiconductor manufacturing acknowledged as being one of the most aggressive processes, so the choice of bearing ring materials is crucial.

A good example is semiconductor manufacturing acknowledged as being one of the most aggressive processes, so the choice of bearing ring materials is crucial.

Bearings for these applications are invariably housed in areas where they need to withstand highly corrosive liquids, gases and plasmas, often at elevated temperatures or in vacuum conditions. This is why Carter offers various bearing options made from stainless steels such as 440C and 316 and also even more exotic nitrogen-enriched stainless steels, such as Cronidur